ABOUT |

Entosol (Australia) Pty Ltd is a registered Australian company, dedicated to the application of chemical-free technologies as solutions to entomological problems. We recognise that pesticide resistance, consumer concern about pesticide use and regulatory constraints have placed considerable pressure on conventional pest control techniques. Our products aim to be compatible with Integrated Pest Management (IPM) strategies adopted within Australasia and provide viable alternatives for pest control professionals.

The company principal, Mr Roger Allanson, is a qualified entomologist, specialising in stored-product insect control for over fifteen years. He was associated with the Australian National Working Party on Grain Protection for 15 years and was a member of the CSIRO Stored Grain Research Laboratory management committee for 8 years. He has also represented the Australian Centre for International Agricultural Research (ACIAR) as an external reviewer for several research projects in China, the Philippines, Malaysia and Indonesia.

The company principal, Mr Roger Allanson, is a qualified entomologist, specialising in stored-product insect control for over fifteen years. He was associated with the Australian National Working Party on Grain Protection for 15 years and was a member of the CSIRO Stored Grain Research Laboratory management committee for 8 years. He has also represented the Australian Centre for International Agricultural Research (ACIAR) as an external reviewer for several research projects in China, the Philippines, Malaysia and Indonesia.

Entosol (Australia) Pty Ltd has developed strong business relationships throughout Australia and south-east Asia in meeting the needs of consumers and industry. Our aim is to provide fast, efficient service aligned with professional technical expertise, to assist our customers with their chemical-free requirements.

Professional Publications:

Allanson, R & Wallbank, B. (1994). Use of methoprene without adulticide as a grain protectant. In "Proceedings of the 6th International Working Conference on Stored-product Protection", 17-23 April 1994, Canberra, Australia. (Eds : E.Highley, E.J Wright, H.J Banks & B.R Champ).CAB International. pp. 734-736.

Cassells, J, Banks, H.J & Allanson, R (1994) Application of pressure-swing absorption (PSA) and liquid nitrogen as methods for providing controlled atmospheres in grain terminals. In "Proceedings of the 6th International Working Conference on Stored-product Protection", 17-23 April 1994, Canberra, Australia. (Eds : E.Highley, E.J Wright, H.J Banks & B.R Champ).CAB International. pp. 56-63.

Waterford, C.J, Whittle, C.P, van S Graver, J.E, Johnston, S.W, Allanson, R, & Weller, G.L (1996). An investigation into safe disposal of phosphine-generating formulations. In "Proceedings of the International Conference on Controlled Atmosphere and Fumigation in Stored Products", Nicosia, Cyprus. (Eds : Donahaye, Navarro & Varnava). CAB International. pp: 311-318.

APPLICATION |

![]() controls all economically important stored grain insect pests including weevils, beetles, borers and moths. It provides 12 months protection against insect pests in:

controls all economically important stored grain insect pests including weevils, beetles, borers and moths. It provides 12 months protection against insect pests in:

- Stored products such as wheat, barley, rice, corn, sorghum, lentils, peas and other food commodities (some constraints apply)

- Warehouses and Storage areas for food products.

- Empty silos and grain handling machinery such as combine harvesters, belt conveyors and bucket elevators.

![]()

Can Also Be Used

Strategically In

Integrated Pest

Management Programs

BENEFITS |

Who Can Benefit From Using  ?

?

- Large Industrial and Government Organizations handling food commodities.

- Farmers, Small Cooperatives, Importers and Exporters storing food commodities and feed or seed grain.

- Flour Mills and Bakeries storing their own grain.

- Feed Producers and Food Processors.

- Brewers

- Poultry, Cattle, Sheep and Pig Farmers and other Stock Producers.

Additional Benefits Include:

- 100% effectiveness against common insect species including those resistant to chemical insecticides.

- Treated grain or other food commodity has no withholding period and can be used any time after treatment.

- Complete protection in normal, vented silos and horizontal storage areas subject to repeated infestation pressure. Sealed storage facilities are not required.

ENVIRONMENT |

![]() is a harmless, non-toxic amorphous silica powder that absorbs the wax on insects. Without their wax coating, insects quickly dry out and die. This non-chemical, environmentally friendly approach to insect control offers major benefits:

is a harmless, non-toxic amorphous silica powder that absorbs the wax on insects. Without their wax coating, insects quickly dry out and die. This non-chemical, environmentally friendly approach to insect control offers major benefits:

No Residue

Treated commodities remain chemical and residue free. This is an important issue for Organic Growers, Exporters and other producers of residue-free food products.

PERFORMANCE |

Whether used for stored commodity protection or structural treatment of warehouses and food stores, ![]() provides very long-term protection, (normally one year or more). This is because the product works by a physical absorption process and does not contain chemicals which can break-down or degrade. Unlike chemical insecticides, it is totally unaffected by high or low temperatures, yet treatment costs are no more than those of conventional chemical treatments for structural treatments.

provides very long-term protection, (normally one year or more). This is because the product works by a physical absorption process and does not contain chemicals which can break-down or degrade. Unlike chemical insecticides, it is totally unaffected by high or low temperatures, yet treatment costs are no more than those of conventional chemical treatments for structural treatments.

The Australian Commonwealth Scientific and Industrial Research Organization (CSIRO) is one of the world's leading research organizations. Much of the basic research and many field trials on ![]() have been conducted or supervised by this organization. They have confirmed its effectiveness. Many grain-growers and Bulk Grain Handling Authorities throughout Australia have adopted

have been conducted or supervised by this organization. They have confirmed its effectiveness. Many grain-growers and Bulk Grain Handling Authorities throughout Australia have adopted ![]() for structural treatment of their handling, transport and storage facilities and/or grain protection.

for structural treatment of their handling, transport and storage facilities and/or grain protection.

Australia's warm summer climate and mild winters create ideal conditions for build-up of insect numbers. ![]() has proven to be very effective despite such high infestation pressure.

has proven to be very effective despite such high infestation pressure.

And Costs?

As a structural treatment, considerable cost savings are achieved. With a dust application rate of 2g/m2, the treatment cost is only about 8% of that of chemical sprays. When sprayed on as a water-based slurry at 6g/m2 (dry basis), the cost is still less than half the cost of chemicals. And unlike chemical sprays, which degrade very quickly in warm summer conditions, the dust remains effective for at least one year.

TREATMENT |

Long-term protection is obtained by treatment of grain at a rate of 1 kg ![]() per tonne. Any powder dosing appliance can be used. The dust is added into a moving stream of the grain at a steady rate to ensure uniform distribution. Typical dosing points are auger hoppers, belt conveyors and bucket elevators.

per tonne. Any powder dosing appliance can be used. The dust is added into a moving stream of the grain at a steady rate to ensure uniform distribution. Typical dosing points are auger hoppers, belt conveyors and bucket elevators.

Aeration of the treated grain should be started immediately if the grain is still warm or has a moisture content too high for long-term storage. This will prevent moisture migration and quality degradation.

Structural Treatment of Empty Silos (By Dust)

![]() requires an air stream to move it onto surfaces and into crevices. For economy and efficiency, we recommend bellows-type dusters, however, any garden duster can be used.

requires an air stream to move it onto surfaces and into crevices. For economy and efficiency, we recommend bellows-type dusters, however, any garden duster can be used.

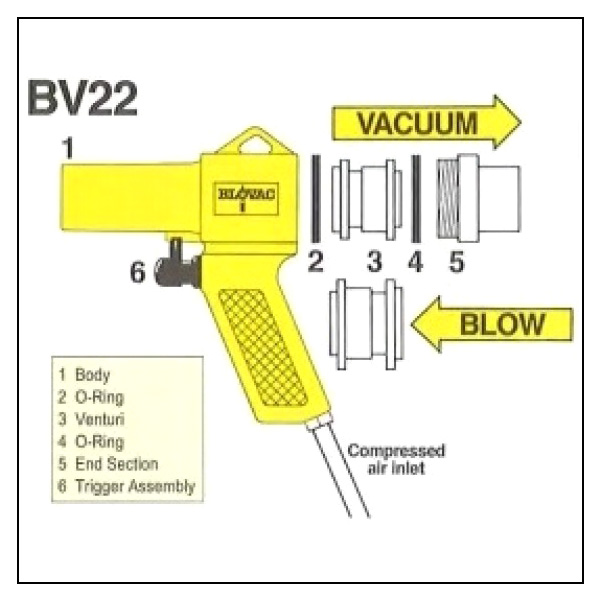

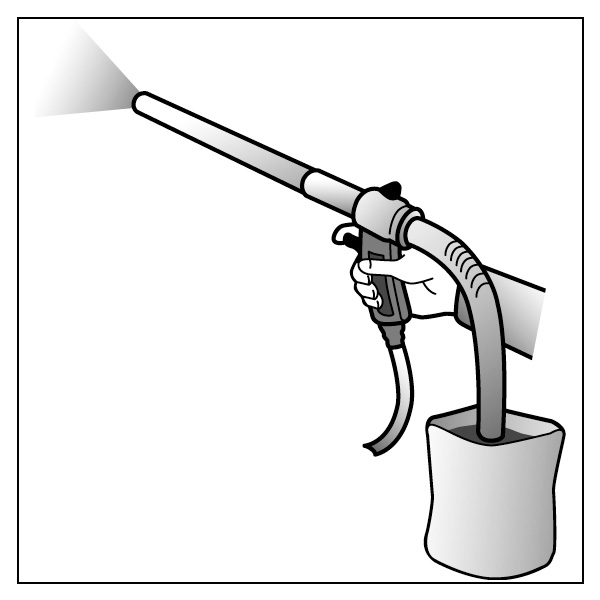

When applying dust to large grain stores, food warehouses or grain handling machinery, venturi blowers, such as the Blovac BV22 unit illustrated, provide the best solution.

These compressed air powered units can also be used to blow, or vacuum away grain debris from equipment and grain stores prior to treatment. Two-stroke, backpack dusters can also be employed.

In order to achieve an even coating on vertical surfaces, dust should be blown through top hatches of vertical silos. If the silo is fitted with an aeration fan, pour the pre-weighted quantity of dust into the fan suction. For horizontal storage areas and warehouses, apply from top to bottom, starting with roof structures. The operator should wear a disposable dust mask when applying dust inside stores or buildings.

By Water-Based Slurry

This novel method of application was developed by the grain industry due to its cleanliness, speed of treatment and excellent control of application rates. However, specialised equipment is required to ensure adequate and reliable treatment of storage surfaces. Application details and equipment recommendations are available.

CONSTRAINTS ON THE PRODUCT’S USE |

As the insecticidal activity of the product lies in its drying properties, very high ambient humidities reduce the effectiveness of ![]() . It is not significant when the periods of high humidity are seasonal, e.g. a wet winter season, however, if high ambient humidifies (70% or more) prevail throughout the year,

. It is not significant when the periods of high humidity are seasonal, e.g. a wet winter season, however, if high ambient humidifies (70% or more) prevail throughout the year, ![]() should be tested in that situation prior to regular use. For the same reason, treatment of damp food commodities should be avoided. Recommended moisture contents for long-term storage protection are:

should be tested in that situation prior to regular use. For the same reason, treatment of damp food commodities should be avoided. Recommended moisture contents for long-term storage protection are:

Wheat, barley and oats - 13% or below

Sorghum, paddy rice and corn - 14% or below

These moisture levels would normally be attained after routine aeration-drying after harvest and storage.

The treatment of grain by any of the commercially available desiccant dust insecticides, including , affects the physical properties of the grain. Flow rates are reduced and the angle of repose is increased. If all of the grain in a silo was treated, difficulties may be experienced in emptying the silo completely. However, with the top layer treatment recommended, the quantity of dust applies is very low and no effects on the handling properties or quality of the grain are experienced. For this reason, DO NOT deliver grain treated with ![]() to grain handling authorities.

to grain handling authorities.

Manufactured and Distributed by:

ENTOSOL (Australia) Pty Ltd

PO BOX 28

ROSELANDS NSW 2196 , AUSTRALIA

Tel: +61 2 9758 4552

Mob: +61 412 522 049

Fax: +61 2 9758 4882

Email: sales@entosol.com.au

APVMA Approval No. 67976/59275

Conditions of Supply:

![]() is manufactured with a high degree of quality control and each batch is individually tested against stored product pests to ensure its efficacy.

is manufactured with a high degree of quality control and each batch is individually tested against stored product pests to ensure its efficacy.

However, as we have no control over the storage, handling, mixing or use of Dryacide, no responsibility will be accepted by us or resellers for any failure in performance, damage, or injury arising from storage, handling, application or use.